Unmatched Valves, Actuators, & Power Units

Announcement: Sale of Refinery Valve Business

Today, we announce the sale of our Refinery Valve Business, comprised of our DeltaValve and TapcoEnpro brands, to Custom Flow Solutions, established by SCF Partners. This move aligns with our strategy to focus on core industrial and aerospace & defense markets.

Press Release

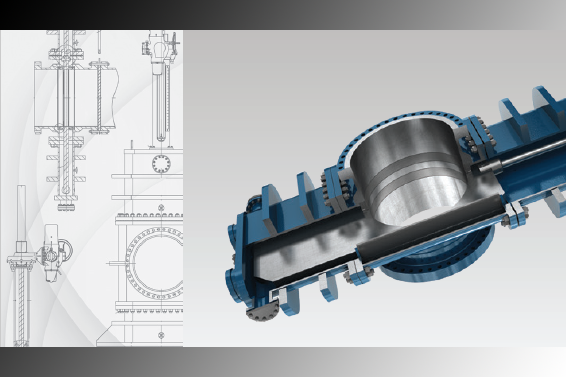

Valves and Valve Products Engineered for Reliability

TapcoEnpro designs and manufactures the world’s most rugged valves and is the leading provider of severe service, critical flow, and high-temperature control valves, electrohydraulic actuators and other essential products and services to the global refining and petrochemical industry. Our multi-step process includes research, conceptualization, feasibility assessment, establishing design requirements, preliminary design, detailed design, production planning, and finally production.

TapcoEnpro valve and actuator service handles the needs of customers throughout the world with the capability to perform complete valve overhauls in the field with an emphasis on safety, quality, and “on time” completion.

Tapco International was founded in 1945. Its primary products were FCCU valves, actuators and hydraulic power units (HPUs). Enpro Systems LTD was founded in 1972 and specialized FCCU valves, vessels and FCCU fabricated equipment. In 2006 these two leading companies merged to become TapcoEnpro.

Today, our design philosophy and techniques of manufacturing have been the standards by which others followed. We constantly push the frontier of valve technology, offering innovative products and services that set the standard for the industries we serve and today, TapcoEnpro's designs and manufactures the world’s most rugged valves.

The engineering design process at TapcoEnpro is a multi-step process which includes research, conceptualization, feasibility assessment, establishing design requirements, preliminary design, detailed design, production planning and finally production.

Our slide valves have been developed to outperform industry standards for safety, performance and reliability and have become the valve of choice for processing facilities, enabling plants to operate safely and without unplanned shutdowns.

- ASME Section VIII Div 1

- ASME Section VIII Div 2

- ASME Pressure Piping

- ASME Steam Boiler

- NBBI Registered

- NBBI R Stamp

- PED / KOSHA / ASTM

- GOST / CSA / JIS / CENELEC

TapcoEnpro constantly pushes the frontier of engineered technology by offering innovative products and services that set the standard for the industries we serve. All products are manufactured in strict accordance with customer specifications and our own quality standards.

TapcoEnpro International is the standard for valve and actuator service. Our Service Division handles the needs of customers throughout the world with the ability and knowledge to perform a complete valve overhaul in the field with an emphasis on safety, quality and “on time” completion.

Whether your turnarounds require in-shop or in-plant, TapcoEnpro is your only source which offers the extensive worldwide support and service necessary to keep your operation functioning and safe.

TapcoEnpro

Reactor Vapor Isolation Valve

TapcoEnpro

Flue Gas Isolation Gate Valves

TapcoEnpro

Expander Inlet Butterfly Valves

TapcoEnpro

Two Port Diverter Valve

CIRCOR delivers customer-focused solutions in strategic global markets‚ where tough challenges‚ harsh environments and high-stakes situations demand precision performance and reliability. To deliver where failure is not an option‚ CIRCOR | TapcoEnpro's commitment to the refining industry is stronger than ever as we continue our tradition of supporting the needs of our customers throughout the world with the ability and knowledge to provide Specialty Valves and Control Systems with an emphasis on safety, quality and “on time” completion.

TAPCOENPRO SERVICE & AFTERMARKET

Your best resource for service,

maintenance and quality parts.

TapcoEnpro’s Service Group is the standard for valve and actuator service. Our Service Division handles the needs of customers throughout the world with the ability and knowledge to perform a complete valve overhaul in the field with an emphasis on safety, quality and “on time” completion.

Our aftermarket division offers repair or replacement spare parts plus complete in-shop repairs and on-site dismantling. Our field service personnel come to your site with a strong belief in exceptional quality and service to our customers.

Our Field Services department oversees all TapcoEnpro equipment installations, commissions, maintenance/repair and onsite training for both valve and control systems. We are focused on attending to our customer's turnaround needs, maintenance and repair requirements.

Our philosophy is that each project requires unique solutions and our approach is a diverse team with specialized engineering competencies, industry prominent quality control, pioneering research and development and superior field service personnel conducting themselves in accordance to the highest safety standards.

Over time, performance of valves and actuators will decrease due to degradation which leads to failure and so there are shutdowns (planned or unplanned) in which improved performance must be addressed. Improvements will come from three areas:

- Minimizing the total downtime during a turnaround. Knowing what to do before the turnaround is an essential piece for improved reliability.

- Maximizing the elapsed time between turnarounds will impact the up-time and profitability of the unit.

- Maintaining reliable performance of the equipment by reducing or eliminating unscheduled downtime.

Our Field Service Group provides a variety of services that are uniquely designed to achieve minimal downtime, maximum run time and maintain reliable performance.

Our team will conduct an on-site evaluation of component conditions to ensure the scope of work is properly defined prior to any turnaround.

Our technical staff has the expertise to develop solutions required for your success:

- Any necessary valve and actuator design modifications

- Analysis and reporting of valve and actuator testing data

- Development of valve maintenance procedures

Prior to your shutdown, our team is available to help minimize your downtime by:

- Review in detail the report from last turnaround.

- Conduct a “hands on” inspection of the spare parts held in inventory and record their existing condition.

- Walk through the unit and determine necessary manpower and equipment required.

- Perform a risk assessment and develop a safety plan.

VIDEO ANIMATION

CIRCOR | TAPCO-ENPRO Isolation Valve

In this video animation, learn how TAPCO-ENPRO's Isolation Valve provides a safer environment when isolating the reactor from the fractionator resulting in safer FCCU operations.

BROCHURE

FCCU Reactor

Fractionator Isolation Valve

A Fluid Catalytic Cracking Unit (FCCU) is expected to operate without interruption for 3 to 6 years. Maintenance requirements include isolating the reactor from the fractionator by placing a physical blind in the reactor overhead line. The manual insertion and removal of the blind flange is one of the most threatening operations in the refinery. There is a need for a safe operator environment for isolation of a hazardous process by eliminating personnel from the operation and emissions of hydrocarbons to the atmosphere.

TapcoEnpro has met the challenge to provide a protected environment during the manual installation of the physical blind by providing automated isolation of the reactor from the fractionator resulting in safer FCCU unit operations.

With sales and service representation worldwide, TapcoEnpro offers custom-designed valves and actuation systems that operate in industrial process applications including Fluid Catalytic Cracking Units (FCC), Residual Catalytic Cracking Units (RCC), Millisecond Catalytic Cracking (MSCC), Reduced Crude Conversion (RCC) and FlexicokingTM Processes.

Corporate office:

TapcoEnpro LLC

16315 Market Street

Channelview, Texas 77530 USA

Phone: (1) 281.247.8100

Fax: (1) 281.247.8281

United Kingdom office:

TapcoEnpro UK

Shawfield Road, Carlton Industrial Estate

Barnsley, UK S71 3HS

Phone: (44) 1226.323160

Fax: (44) 1226.732312

GENERAL

Phone: + (1) 281-247-8100

SALES

Email: tapcoenpro@circor.com