Acumen for Accuracy

Precision is everything. Consistency is everything else.

Zenith precision-gear metering pumps provide accurate‚ reliable‚ pulse-free metering performance over a wide range of process applications and fluid conditions.

When it comes to the high expectations for metering pump systems, Zenith delivers with accurate, reliable and pulse-free performance. Serving the food and beverage, nutraceutical and personal-care markets, we strive to deliver the greatest value at the lowest total cost of ownership with every solution.

Since 1926, the Zenith Pump brand has offered engineers pulse free precise flow with low NPSH (net positive suction head) requirements. These positive displacement pumps utilize an intermeshing gear system that rotates within a housing. As the gears rotate, a void is created drawing the material into the pump. The tight operating tolerances of the gears and available material options for the housing provide significant advantages in fiber, polymer processing, adhesives, paints, food and other markets.

As part of the CIRCOR family of brands, we combine exceptional engineering with a focused attention to your needs—from cost to overall product appeal—attention that’s always backed by an experienced support team.

Precision, with consistency, is everything. That’s why we design and tailor your metering pump systems to any process application, including dosing, filling, injection, coating, coloring, flavoring, extruding, spraying and fiber spinning. We can accommodate fragrance metering, colorants, fillers, antioxidants, surfactants, emulsifiers, preservatives, adhesives and expensive trace ingredients—hot, cold, corrosive, viscous, shear-sensitive, you name it.

Certifications

MFG in Monroe NC USA

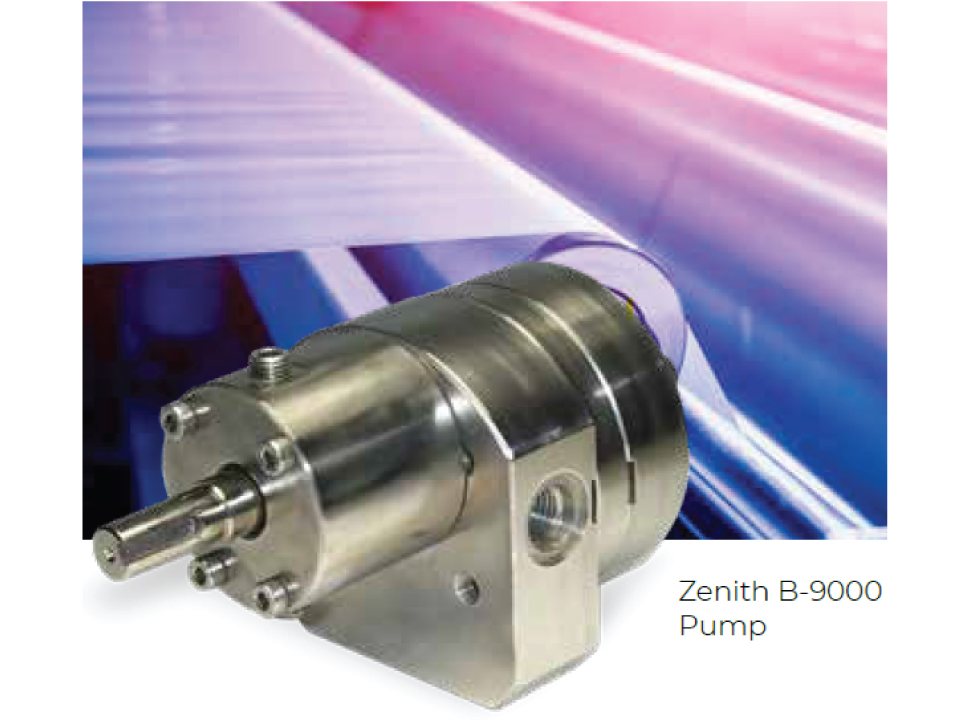

The 9000 series metering pumps are designed to deliver accurate and repeatable flow of metering additives, colorants, hydrogen fuel cell MEA gasketing sealant and adhesive application, or chemicals in a compact and efficient design.

400SS, 316SS, Tool Steel

Max. Pressure [psi] :2,500

Avail. Cap. Range [cc/min] :27,000

Max. Outlet Pressure [PSI] :2,500

MFG in Monroe, NC USA

For chemical and polymer fluid metering applications. B-Series pumps have an “outer drive gear” design that allows pumps to be driven by a common pinion gear or multiple pinion gears on a line shaft.

0.16 - 2.92

Max. Flow Rate [GPH] :8.3

Max. Fluid Temperature [°F] :300

Max. Viscosity [CP] :100,000

MFG in Monroe, NC USA

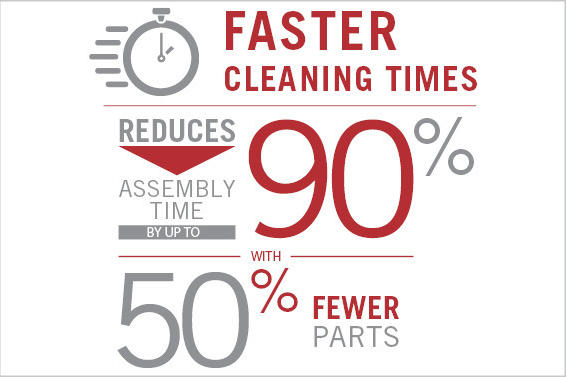

For polymer extrusion applications where product uniformity is critical. BB PEP Series pumps are specifically designed for medical tubing applications where high precision and ease of disassembly and cleaning are desired.

750

Max. Flow Rate [lbs/hr] :7,000

Max. Fluid Temperature [°F] :950

Max. Disch. Pressure. [PSI] :10,000

MFG in Monroe, NC USA

For polymer fluid applications at high temperatures, pressures and viscosities as well as for abrasive fluids.

24,000

Max. Pressure [psi] :4,000

Max. Fluid Temperature [°F] :950

Shaft Seal :Graphoil Packing Seal or Universal Coupling Seal

Precision, with consistency, is everything. That’s why we design and tailor your metering pump systems to any process application, including dosing, filling, injection, coating, coloring, flavoring, extruding, spraying and fiber spinning.

Solutions for Adhesives and Sealants

Zenith Pumps for Paints and Coatings

For dependable control of critical coating applications. High accuracy eliminates costly over-application associated with less accurate methods, and the pumps often pay for themselves in savings in one year or less.

Zenith Pump Solutions for Filtration Production

Zenith pumps and systems are used in a range of applications in a variety of markets. Generally, Zenith pumps meter chemical solutions; yet the requirements of each generic metering function can be industry specific. Zenith pumps applications are classified as dosing, filling, injection, coating, extruding, spraying or spinning.

Zenith pumps feature a wide operating flow, pressure and temperature range capable of handling abrasive, corrosive, hot, cold, viscous, toxic and shear sensitive fluids.

- Minimum – Maximum Flow Rate = 0.16 – 27,000 cc/rev

- Maximum Viscosity = 1,000,000 cps

- Maximum Pressure = 4000 psi

- Maximum Temperature = 900F

A general overview of the applications that we participate in is provided below; however, we encourage you to contact Zenith to discuss your specific requirements.

| Application | Markets | Applicable Pumps |

|---|---|---|

| Dosing | General Industry/Pharmaceutical General Industry/Chemical Process General Industry/Pulp and Paper General Industry/Food and Beverage |

B Series H Series 9000 Series |

| Fill | General Industry/Food and Beverage General Industry/Chemical Process |

B Series 9000 Series |

| Injection | Oil and Gas Power Generation General Industry/Fiber General Industry/Plastic Extrusion General Industry/Chemical Process General Industry Pulp and Paper |

PEP II 9000 Series B Series H Series |

| Coating | General Industry/Pharmaceutical General Industry/Food and Beverage General Industry/Chemical Process |

9000 Series B Series H Series |

| Extrusion | General Industry/Food and Beverage General Industry/Fiber General Industry/Chemical Process General Industry/Plastic Extrusion |

PEP II BB PEP 9000 Series H Series |

| Spraying | General Industry/Fiber General Industry/Chemical Process General Industry/Paints |

H Series 9000 Series B Series Flushable |

| Fiber Spinning | General Industry/Fiber | Spin Finish Planetary |

CIRCOR delivers customer-focused solutions in strategic global markets‚ where tough challenges‚ harsh environments and high-stakes situations demand precision performance and reliability. To deliver where failure is not an option‚ CIRCOR | ZENITH brings customers a portfolio of pumping products and systems and deep experience and expertise in critical applications.

CIRCOR | Zenith brings the markets of Chemical Process, Pulp and Paper, Fiber, Extrusion, Paints and Wastewater together under a primary Industrial market definition. Many of the applications within this segment are for process support; however, there remains a wide breadth of applications and variance in process conditions.

Zenith branded pumps have a successful history of supporting engineering and operators within the segments of Industrial market. Known for the reliable, smooth pulse free operation Zenith pumps are typically called on to meter chemicals, plastics, paints or other additives supporting either a specific process operation or final product.

The Zenith pump applications for the Industrial market include:

VIDEO

Redefining what's possible for your business

Zenith gear pumps from CIRCOR have been the top choice of manufacturers since 1926, and rightly so!

With high metering accuracy, pulse-free flow, and long wear life across various fluid and pressure conditions, Zenith is synonymous with optimal performance and reliability.

Watch the video to learn the markets and applications that Zenith pumps support.

AFTERMARKET & SERVICE

Your best resource for service,

maintenance and quality parts.

No one knows your valves, pumps and systems like the experts at CIRCOR. Our certified OEM parts are engineered to meet or exceed original equipment standards and our service and support teams are equipped with some of the best knowledge in the industry. We have the resources to troubleshoot, analyze and solve even your most complex issues in ways other service options are unable to.

CASE STUDY

A global plastic bag manufacturer and Zenith Pumps roll out a revolutionary new way of making scented plastic bags

Our customer is a global manufacturer of scented plastic garbage bags. Zenith’s precision gear metering pump solution provided a continuous pulse-free process that gave them accuracy and consistency at the low flow rates required. Have a look at our new Zenith scented plastic bags case study at the link below.

Case Study

Loud and Clear Solution for Automotive Noise and Vibration Product Reduction Manufacturer

Our customer is a leading expert in the global market for automotive noise vibration harshness solutions Their products reduce noise and vibration that come from the engine, drive train and the friction with the road, all of which diffuse to the chassis of the vehicle.

MEDICAL TUBING

Zenith Precision Extrusion Gear Pumps for Improved Uniformity and Accuracy

THE ZENITH SOLUTION

By utilizing a Zenith Precision Extrusion Gear Pump on a medical tubing line, manufacturers can more effectively control the melt delivery to downstream equipment. The pump meters the flow through the die thus achieving a controlled melt quality and reduced melt temperature, ensuring a product that’s reliable, repeatable, and economical. Additional benefits are reducing the back pressure on the extruder to minimize resonance time and stabilize the plasticizing action of the extruder.

FROM PLANT TO PRODUCT

Zenith Dispensing Pumps for Cannabis Market

When requirements for precision flow control arise in emerging industrial markets, Zenith is on the case. In the fast-growing cannabis market, our metering gear pumps can help the process chain get product out of plant material and into a consumable with pumping solutions for extraction and distillation as well as dosing, injecting and spray coating. Have a look at our new From Plant to Product flyer.

ZENITH SERVICE PORTAL

For our registered customers and partners we provide important technical information, documents and services in our ZENITH Service Portal around the clock.

CIRCOR | Zenith

Precision Metering

1710 Airport Rd, Monroe, NC 28110

877-853-7867

704-289-6511

Terms and Conditions of Sale