Setting Standards, Surpassing Expectations

Smooth, silent performance

With millions of pumps currently in service around the world, Imo’s reputation for quiet, continuous reliability has a lot of momentum behind it.

In 1931, Carl Montelius joined financier Bengt Ingeström to form IMO, a name formed from their combined initials. Today, the brand continues in the tradition of these two prominent men, representing the highest quality, reliability and service levels in the pump industry.

CIRCOR Pumps North America LLC is a leading marketer and world-class manufacturer of Imo Pump products with competitive advantages. By developing supplier‚ distributor and customer networks for various industries and market segments‚ we achieve global reach.

Manufacturing rotary positive-displacement three-screw and gear pumps, the Imo Pump brand meets the strict requirements of our customers' applications and can offer precise‚ and reliable performance. Our experienced engineering staff can help you solve any design‚ engineering or process issue.

Industries served include hydrocarbon and chemical processing‚ crude oil transport‚ Navy and commercial marine‚ power generation‚ pulp and paper‚ hydraulic elevator and general machinery.

Manufacturing is accomplished under ISO 9001 Management Systems. We have also received TS 16946 certification‚ the highest automotive quality standard issued.

Certifications

MFG in Monroe, NC USA

Series 6D IMO® pumps are intended for high pressure service on fluids with viscosity from 2cSt to 25,000ssu.

1,500

Max. Flow Rate [GPM] :400

Max. Viscosity [mm²/s] :5,400

Max. Fluid Temperature [°F] :250

MFG in Monroe, NC &

Columbia, KY USA

The 3D series pumps is a general purpose design suitable for many applications including lubrication, fuel transport and burner service, low pressure hydraulic applications and hydraulic elevator service.

500

Max. Flow Rate [GPM] :400

Max. Viscosity [mm²/s] :3,250

Max. Fluid Temperature [°F] :250

MFG in Monroe, NC USA

Series 12D Imo pumps are intended for relatively high pressure service on petroleum or similar viscosity liquids.

2,200

Max. Flow Rate [GPM] :400

Max. Viscosity [mm²/s] :5,400

Max. Fluid Temperature [°F] :225

For a leak- and trouble-free operation. Innovative technology featuring magnetic couplings drastically reduces wear. The special design of the screws creates sealed chambers that precisely direct the liquid flow from the suction to the discharge side.

1.200

Max. Outlet Pressure [bar] :16

Max. Differential Pressure [bar] :16

Max. Fluid Temperature [°C] :180

Viscosity Range [mm²/s] :1,4-1.500

Based on the latest technology and are ideally suited for use in hydraulic applications up to 250 bar. Known for their exceptional reliability, maintaining productivity and minimizing downtime.

1.050

Max. Inlet Pressure [bar] :10

Max. Outlet Pressure [bar] :250

Max. Fluid Temperature [°C] :155

Viscosity Range [mm²/s] :1,6-400

MFG in Monroe, NC USA

Series 324A is a double suction design providing relatively high flow rates in a compact pump. These are commonly used for machinery lubrication, fuel oil transfer and burner services and for asphalt and vacuum tower bottoms processing and transfer.

43,200

Max. Flow Rate [GPM] :900

Max. Diff Pressure [PSI] :500

Max. Speed [RPM] :1,800

Max. Capacity [GPM] :900

Made in Germany

IMO LB6D series pump is used in high-pressure pipeline applications such as Lease Automatic Custody Transfer (LACT).

180

Max. Fluid Viscosity [°F] :176

Max. Inlet Pressure [PSIG] :100

Max. Viscosity [cSt] :760

CIRCOR three screw pumps from IMO incorporate a positive displacement rotary design consisting of a housing, which envelops the drive screw (power rotor) and the sealing screws (idler rotors).

The intermeshing of the threads of these rotors, along with the close fit of the surrounding housing, creates a moving labyrinth seal, which captures the valuable fluid and transports it axially. The enclosed area containing the fluid is referred to as a fluid closure. The pumping element does not pre-compress the fluid, but rather transports it from the suction side of the pump to the discharge port in a smooth, continuous manner. It is the fluid closure concept that provides the three-screw pump with its positive displacement capability.

Symmetrical pressure loading on the power rotor eliminates the need for bearings to absorb radial forces. The idler rotors generate a hydrodynamic film, which provides radial support similar to journal bearings. Axial loads on the power rotor and idler rotors, created by differential pressure, are hydrostatically balanced. This dramatically increases the life of the pump.

Strengths of the three-screw pump technology:

- High pressure boost capabilities, even when handling low viscosity fluids

- One of the highest overall efficiencies when handling heavy crude 3

- Simple pump design with only three rotating parts and one shaft seal

- Designs available to the latest edition of API 676

AFTERMARKET

Your best resource for service, maintenance and quality parts.

No one knows your valves, pumps and systems like the experts at CIRCOR. Our certified OEM parts are engineered to meet or exceed original equipment standards and our service and support teams are equipped with some of the best knowledge in the industry. We have the resources to troubleshoot, analyze and solve even your most complex issues in ways other service options are unable to.

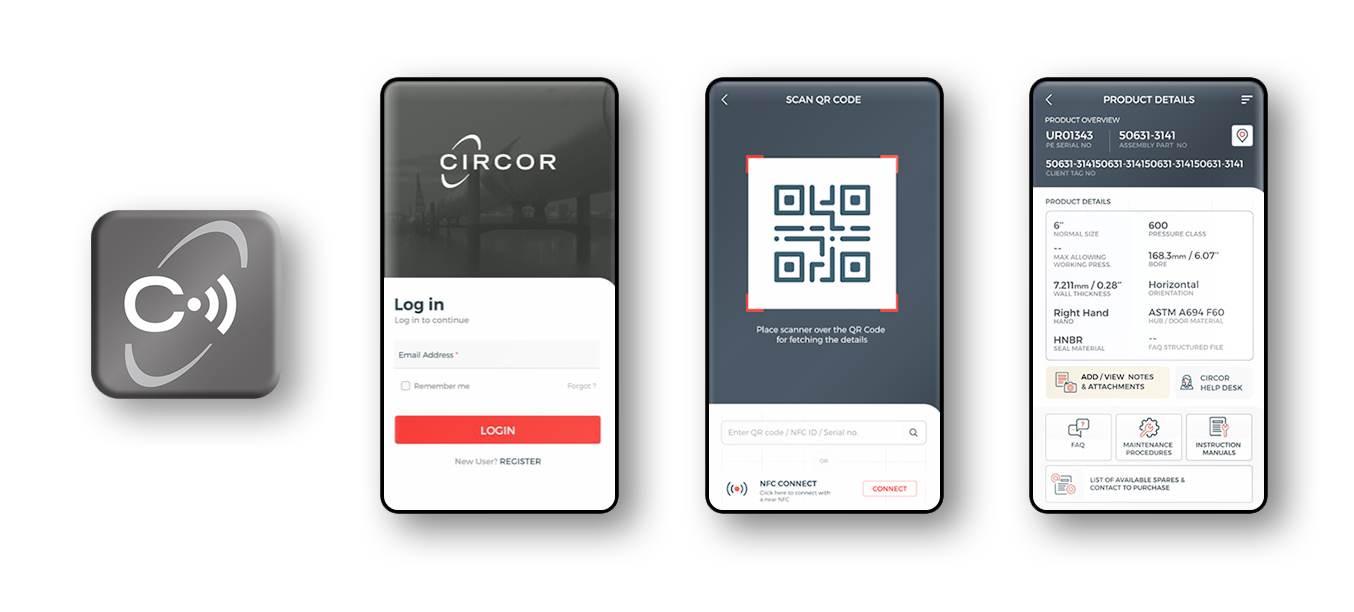

CIRCORSMART™

PUTTING CRITICAL DATA AT YOUR FINGERTIPS.

The app designed to make your life easier.

CIRCORSmart is an invaluable tool for keeping track of CIRCOR | IMO products and their maintenance requirements. CIRCORSmart allows operators and maintenance technicians to track maintenance on each product, take detailed notes and store them, and attach photos and important files for future use. The ability to keep track of product maintenance information at all times contributes to reduced downtime. With CIRCORSmart, accessing the info you need has never been easier. If your manufacturing operations use IMO product Series 3E, 3G, 3D, 6D or 12D pumps. This app is a must have for maintaining the health of your critical pump equipment.

BROCHURE

Hydraulic Elevator Systems

The vast majority of today’s elevators are one of two basic designs, traction or hydraulic. Hydraulic types of systems are typically less expensive and are found in buildings with a maximum of six or seven floors. These systems typically feature a rotary three-screw pump because of the pump's quiet, smooth and reliable operation.

PROVEN PUMPS. ENGINEERED TO LAST.

With pumps like the cast iron 3D Series from IMO or the sturdy construction of the 4PIC and ALLift® Pump Series from Allweiler, CIRCOR offers a variety of options that will deliver decade upon decade of flawless performance.

BACK TO BASICS

A Pre-Startup Guide To Rotary Pumps: Part I, By Simon Bradshaw

Follow these tips to help keep gremlins away from your system.

Many pump startups are the culmination of months, if not years, of work to design the process, machine or system; specify components, instrumentation and protective devices; and review and qualify suppliers. It is also the most vulnerable time for any pump. Part I of this article describes cautions, reviews and inspections for three main components that should be conducted before startup to help ensure that gremlins of pumping systems are identified and eliminated. In a future issue, Part II will give additional tips on how to prevent delays and other, last-minute pointers to ensure successful startup of rotary pumps.

BACK TO BASICS

A Pre-Startup Guide To Rotary Pumps: Part II, By Simon Bradshaw

Follow these tips to help keep gremlins away from your system.

Part I of this article, as seen above, described cautions, reviews and inspections for three main components (piping and valves; foundation, alignment and rotation; and lubrication) that should be conducted before startup to ensure the issues that can arise with pumping systems are identified and eliminated. This article, Part II, reviews additional information on how to prevent delays and ensure the successful startup of rotary pumps.

IMO SERVICE PORTAL

For our registered customers and partners we provide important technical information, documents and services in our IMO Service Portal around the clock.

DEFENSE/NAVY INQUIRIES

Email: cedric.levert@circor.com

CIRCOR Pumps North America, LLC

1710 Airport Rd.

Monroe, NC 28110

1 (704) 289-6511 (International)

1 (877) 853-7867 (USA and Canada)

Terms and Conditions of Sale

GENERAL

Phone: +46 8 506 22 800

Fax: +49 (0)7732 86-929

Email: Sales.IMOAB@circor.com

CUSTOMER SERVICE

Email: cc@circor.com

ALLWEILER GmbH

Allweiler Straße 1

78315 Radolfzell

Germany