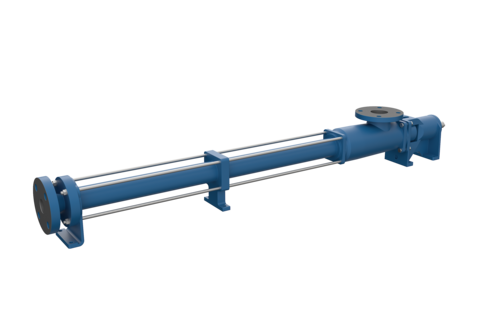

Allweiler AE.V-ID Series Progressing Cavity Pump

AE.V-ID

The AE.V is a universal Progressing Cavity Pump for pumping neutral or corrosive liquids, uncontaminated or abrasive liquids, liduis containing gases or which tend to froth and liquids of low or high viscosity including liquids containing fibrous and solid material.

General Information

Base plate design (pump and motor mounted on a base plate)

Pedestal mounting

Dry installation

Horizontal installation

Bearing bracket design

Pump drive directly coupled or by gear or belt transmission

Self - priming

Reversible pumping

Other data

Data

Series AE.V-ID

Capacity Q up to 2900 l/min

Discharge pressure pd up to 48 bar

Differential pressure pdiff up to 48 bar

Viscosity v up to 270000 mm²/s

Fluid temperature t up to 150 °C

No. Stages - up to 8 -

Low pulsation

Self priming

Low shear & gentle fluid handling

Bi-directional flow capability (CW & CCW)